Decoration Laser Cutting Technical Support

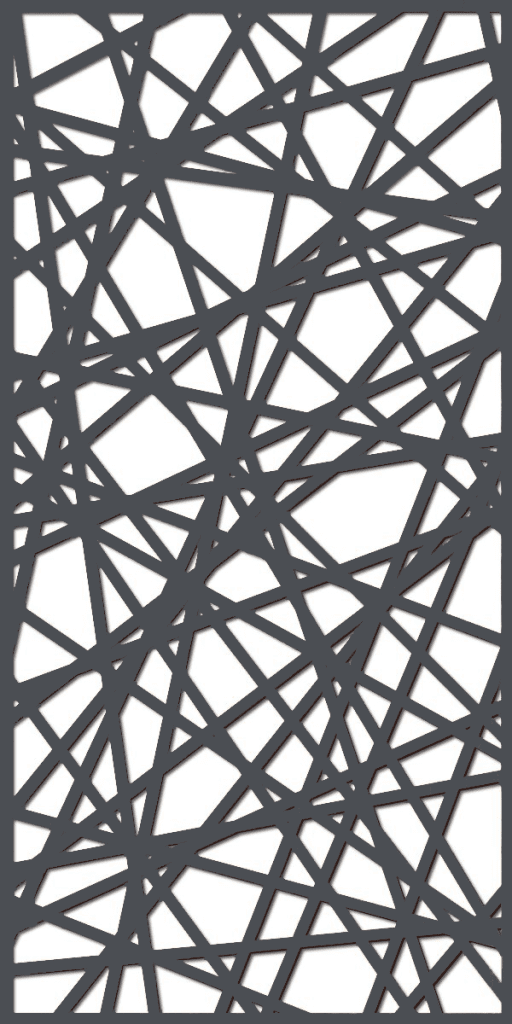

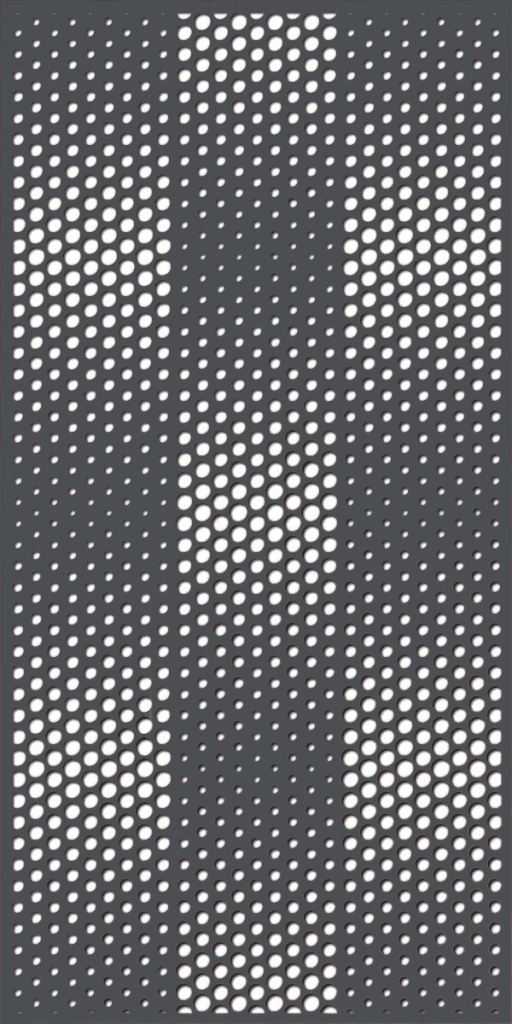

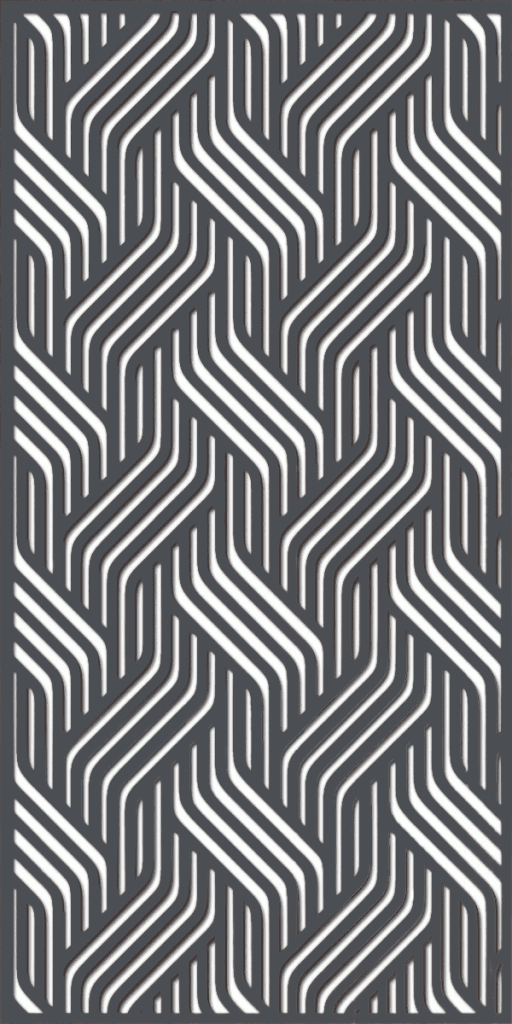

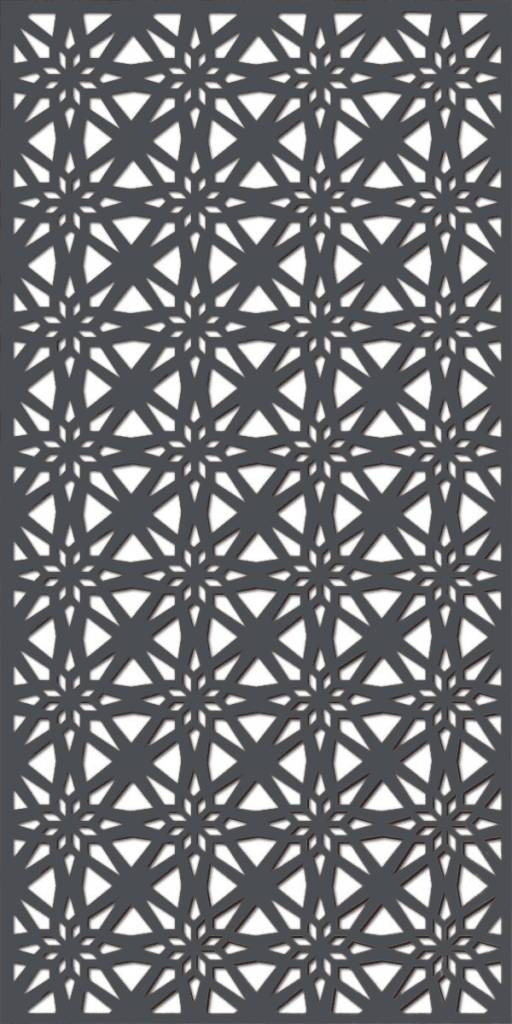

This paper mainly marks the introduction of laser cut metal panel and pattern selection, you can choose the pattern in the following graphics can also be customized pattern.

The laser cutting panel is manufactured by a CNC plane laser cutting machine.Laser cutting processing is to replace the traditional mechanical knife with invisible light beam, with high precision, fast cutting, cutting patterns are not limited, smooth incision, the use of CAD drawing and typesetting, improve production efficiency and save materials.

The products processed by this equipment have the characteristics of beautiful appearance, diverse shapes, strong integrity and good flatness, large size processing etc., and are widely used in indoor wall decoration, room partition, ceiling decoration, and outdoor enclosure, facade decoration, sunshade, decorative barrier/machine equipment protection.

Material

The panels are made of iron, stainless steel and aluminum. Generally more choose aluminum.

Surface Treatment

Different surface treatments are available according to different colors and different materials, from polishing, paint, powder coating to PVDF.For outdoor decoration, powder coating and PVDF are common.Meanwhile PVDF is best choice,Because it has the effect of anti-ultraviolet color retention time; For interior decoration, metal primary polished, powder coating may be better.

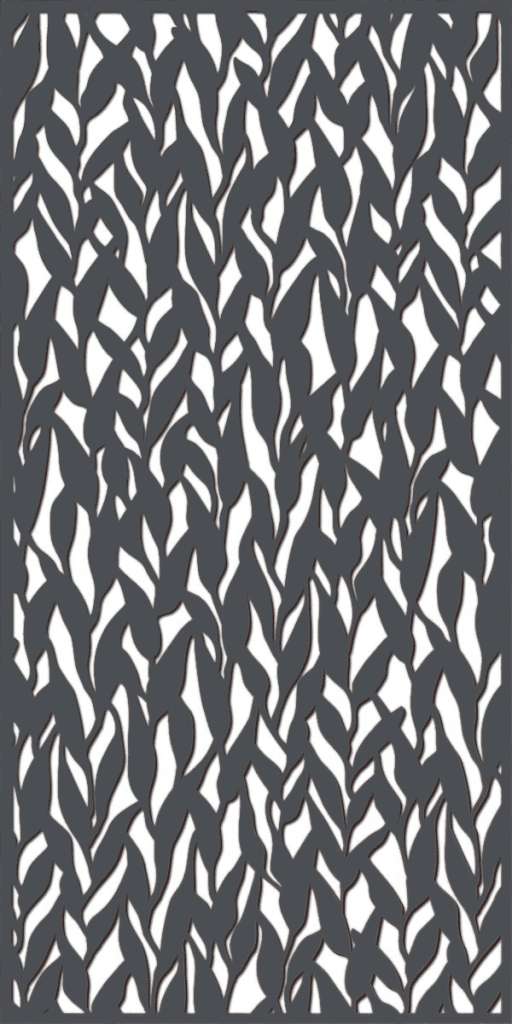

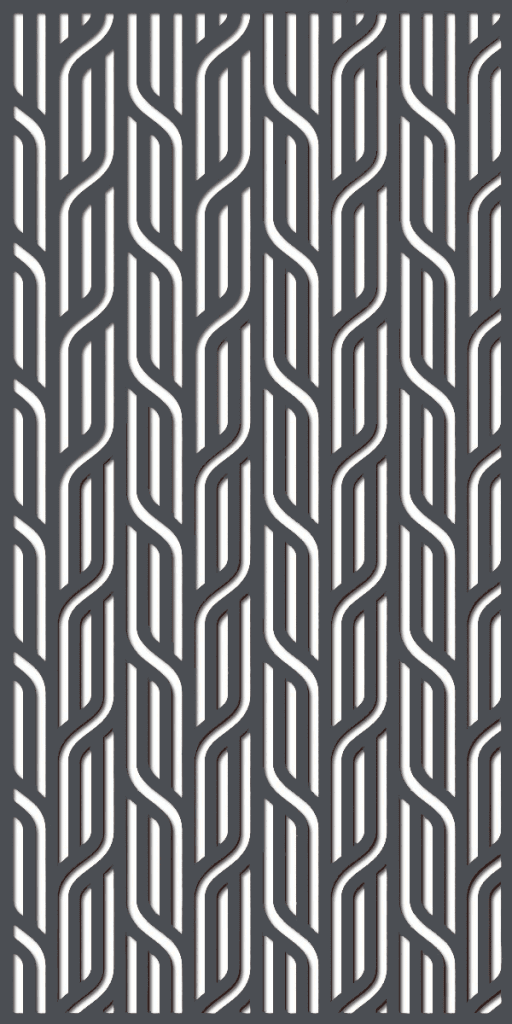

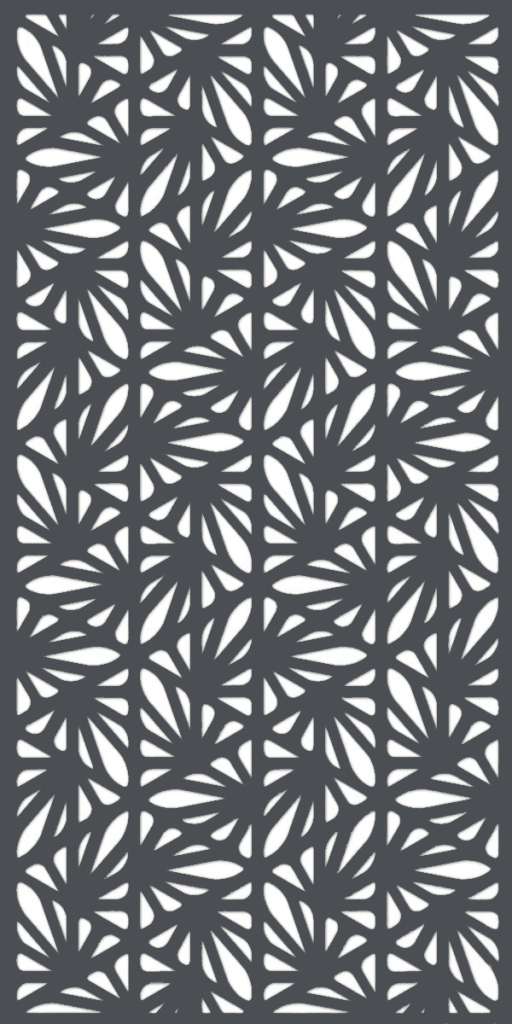

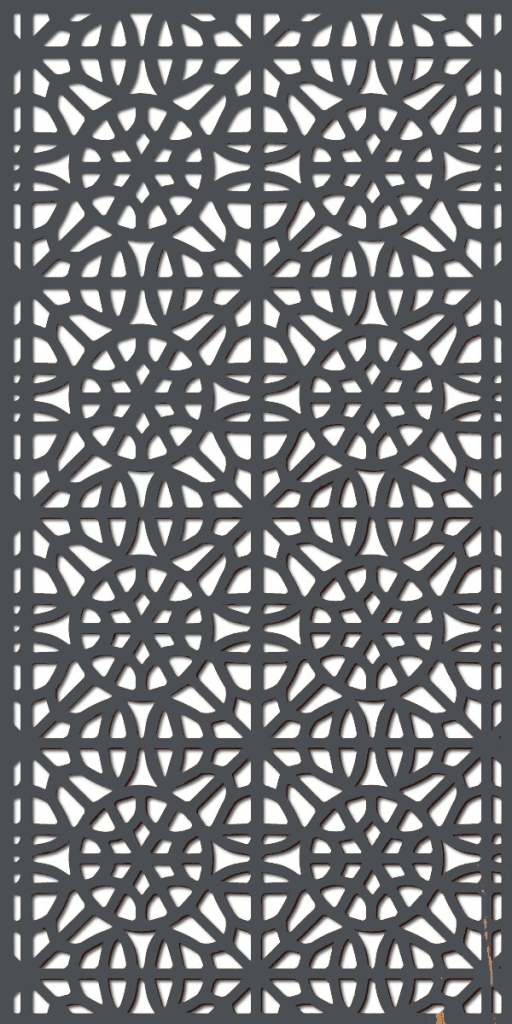

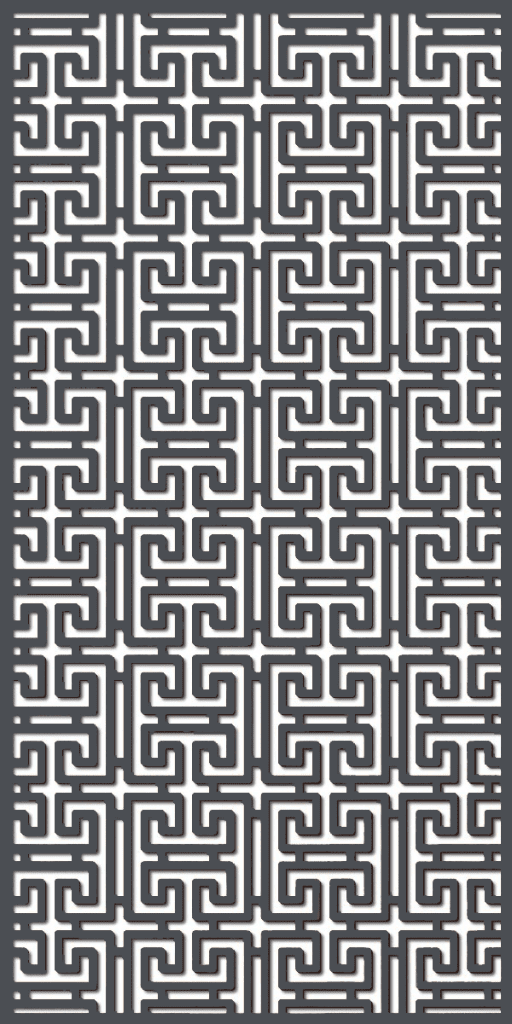

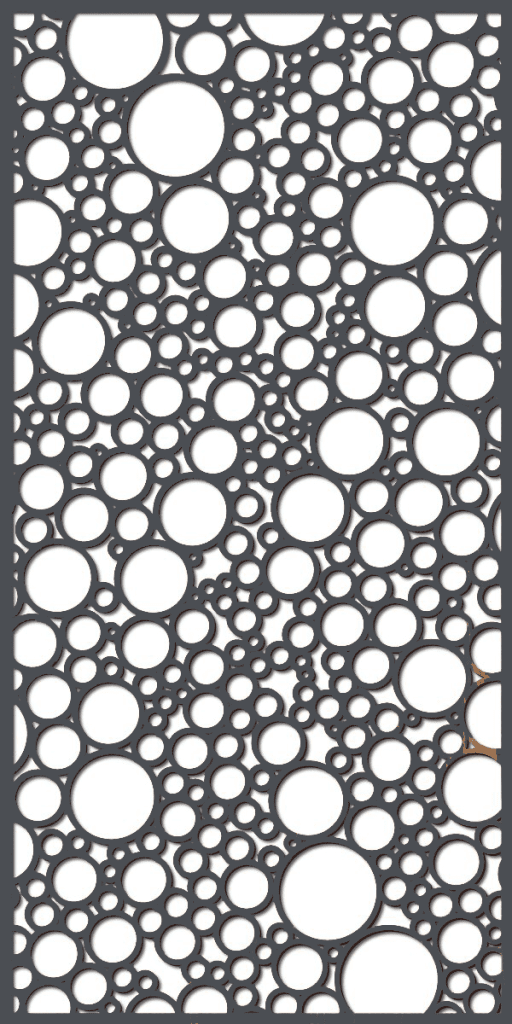

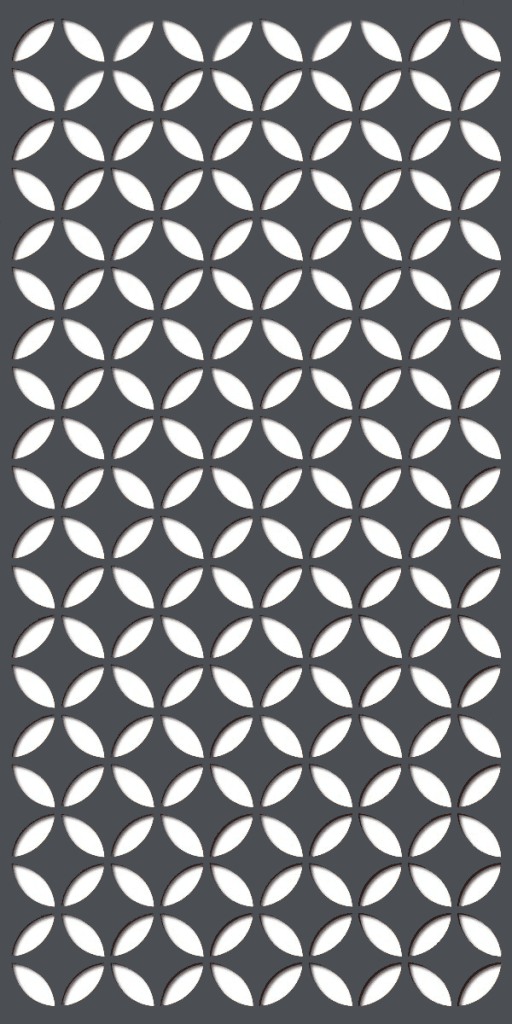

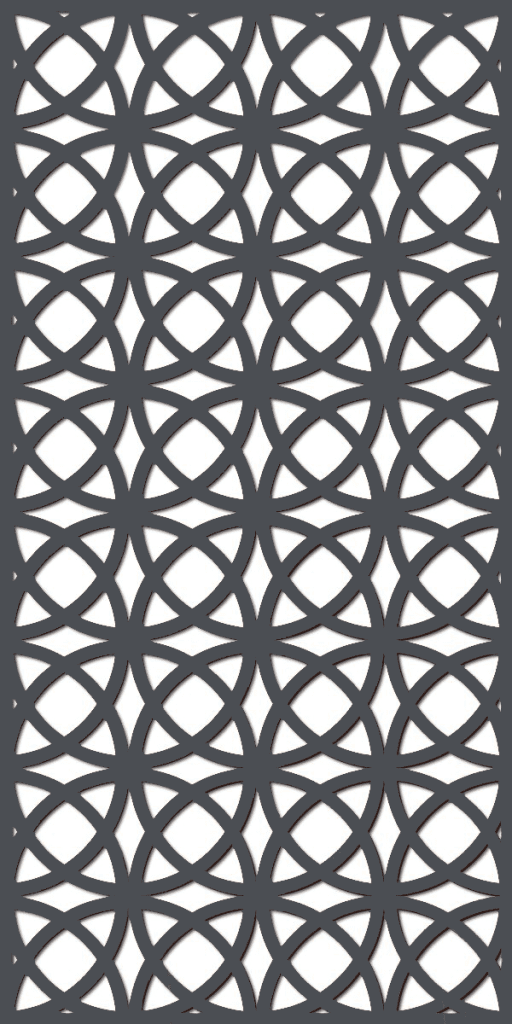

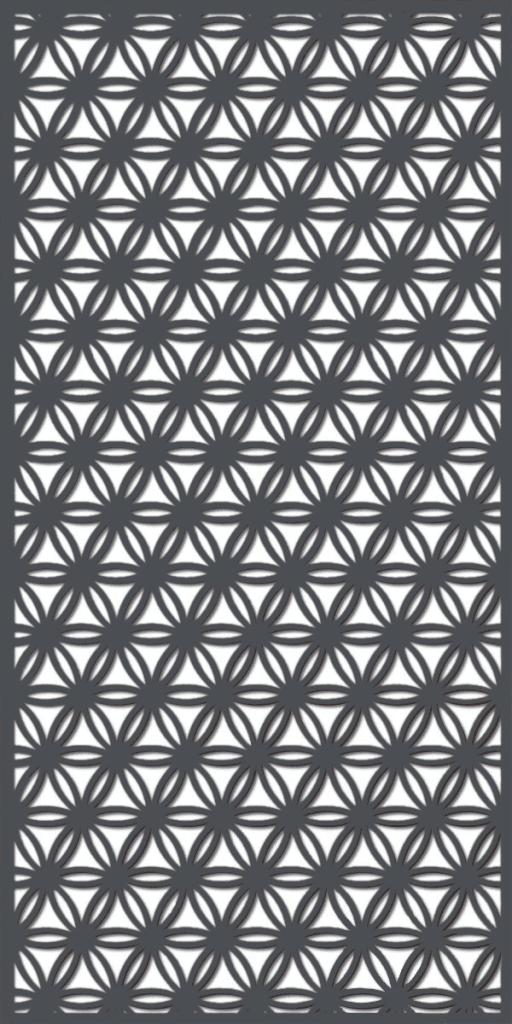

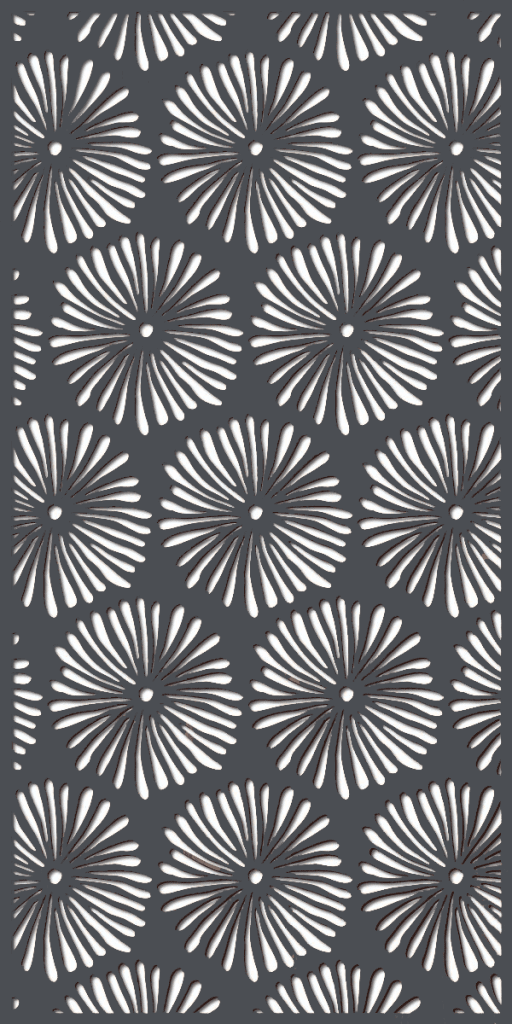

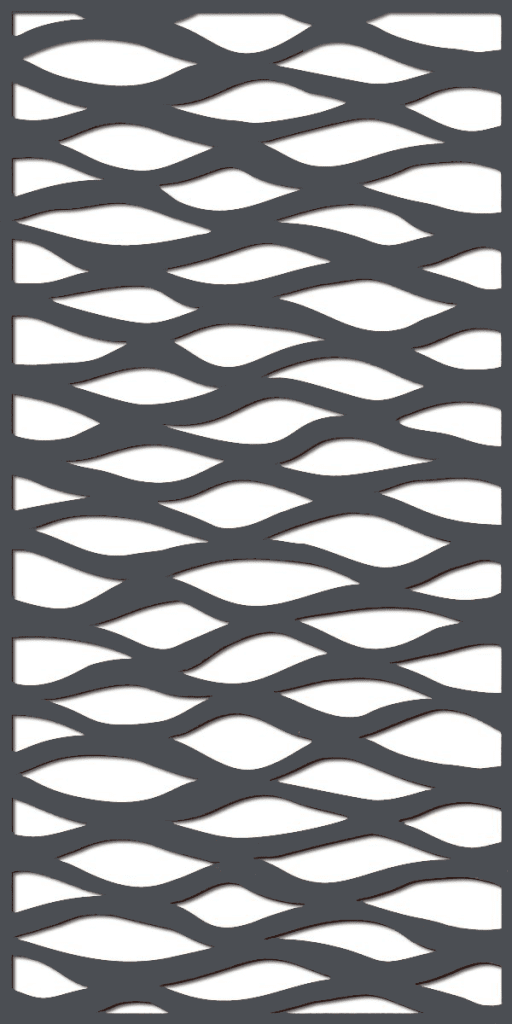

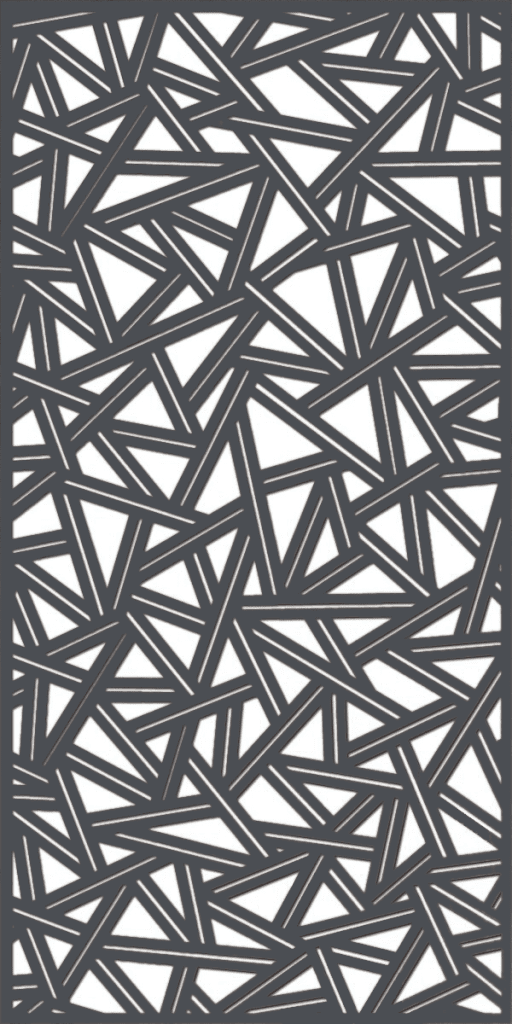

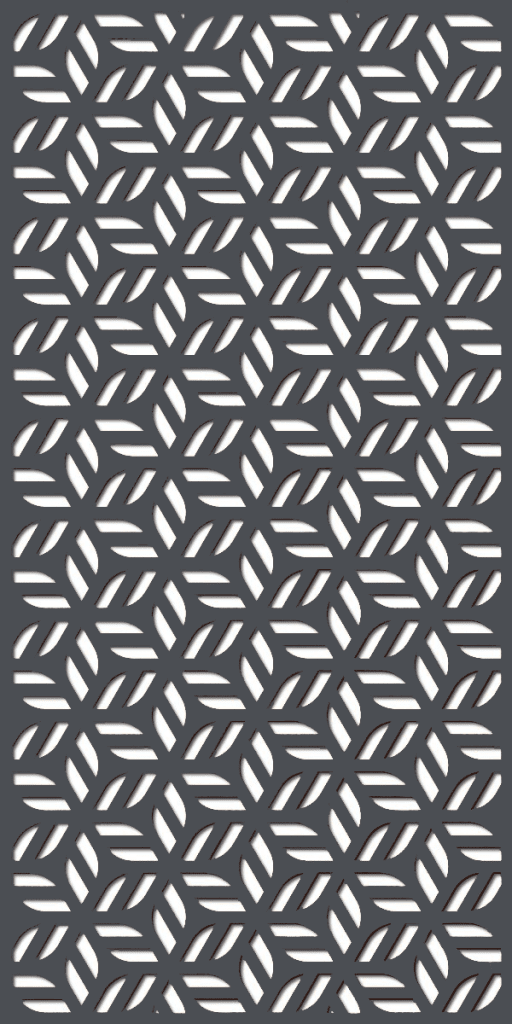

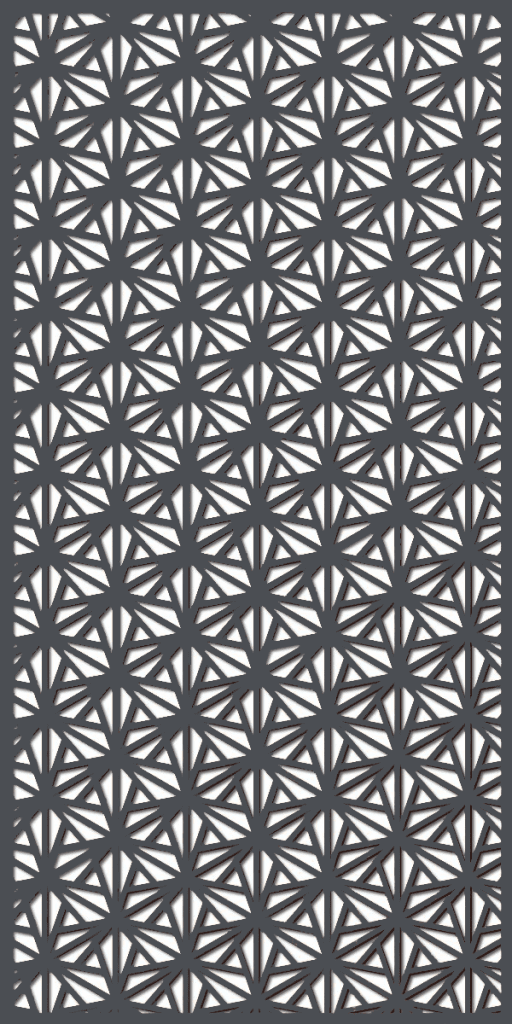

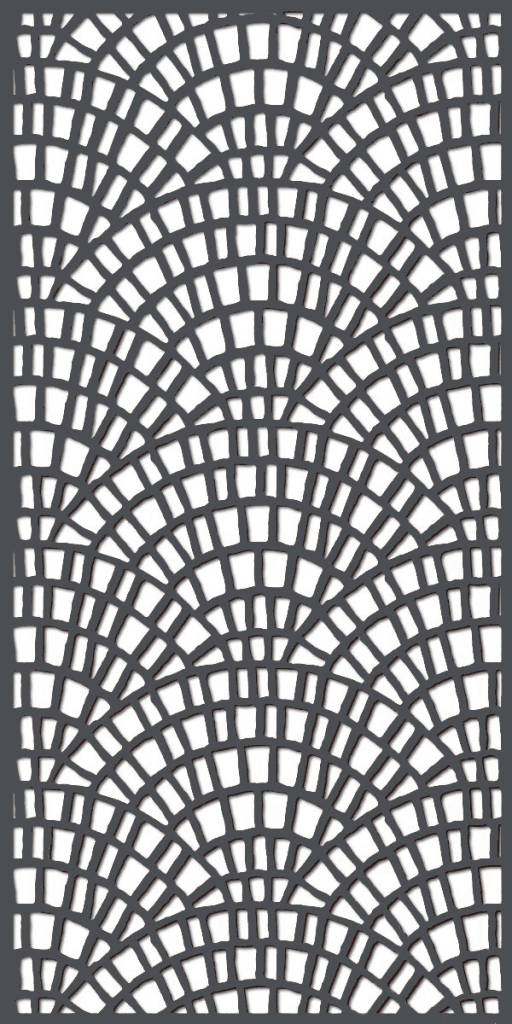

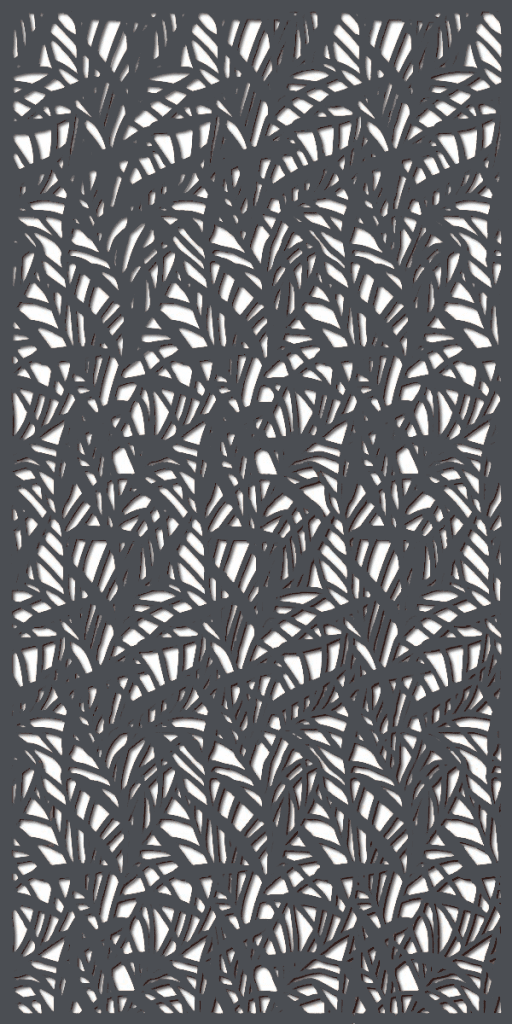

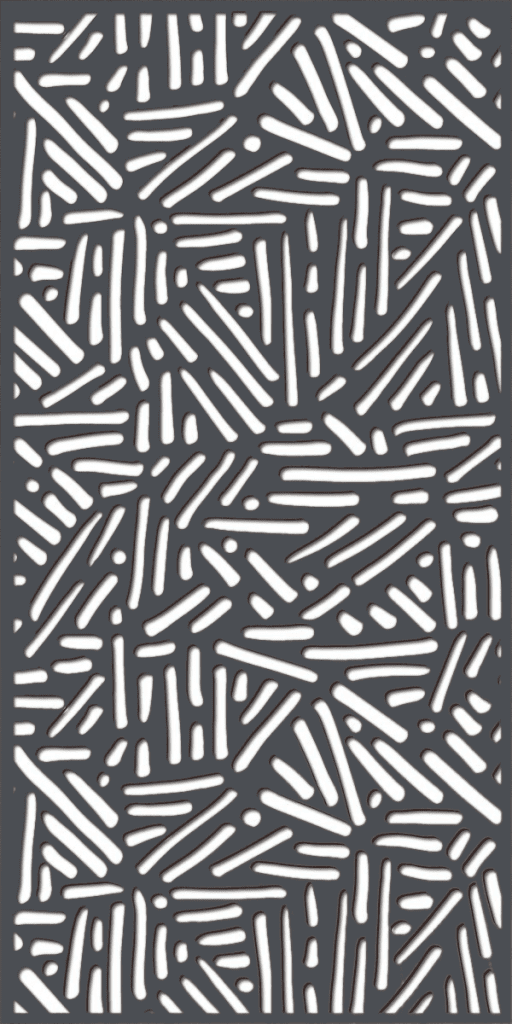

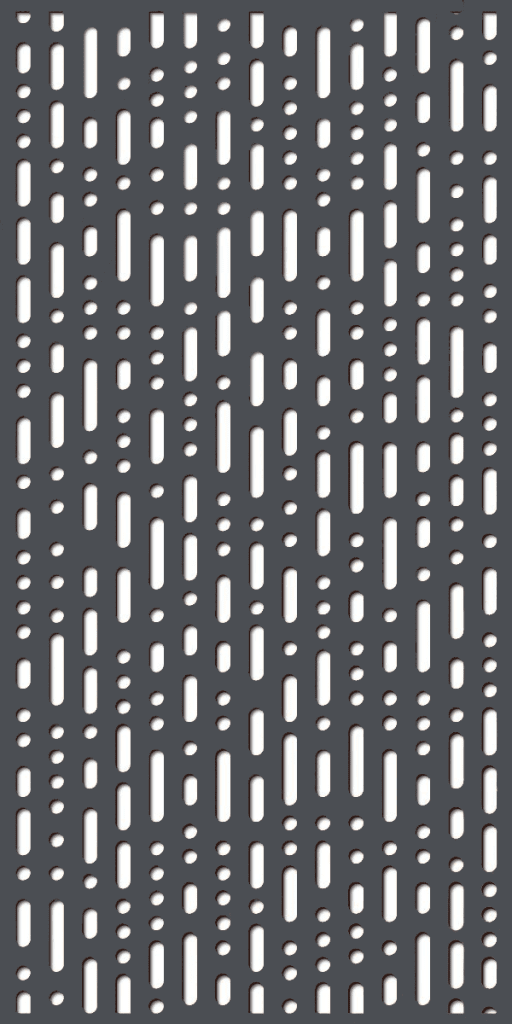

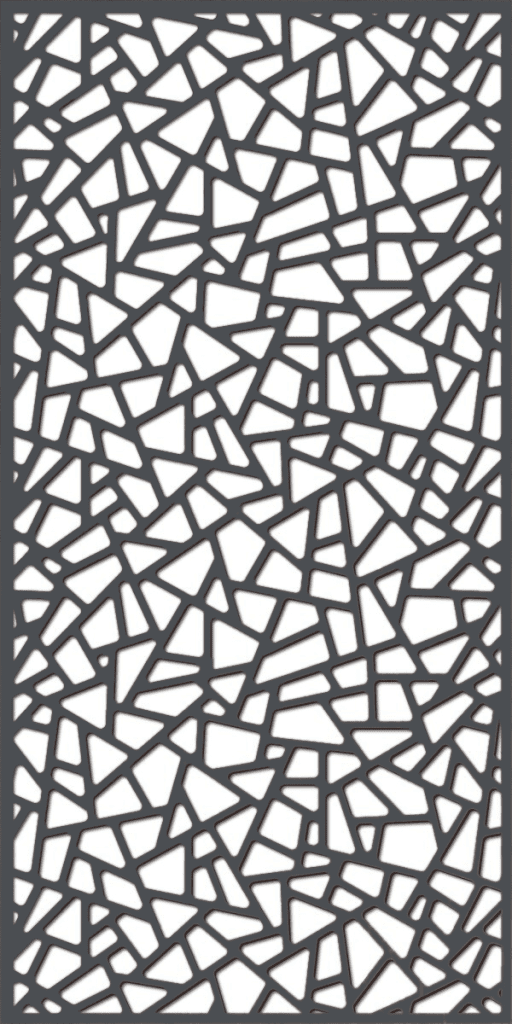

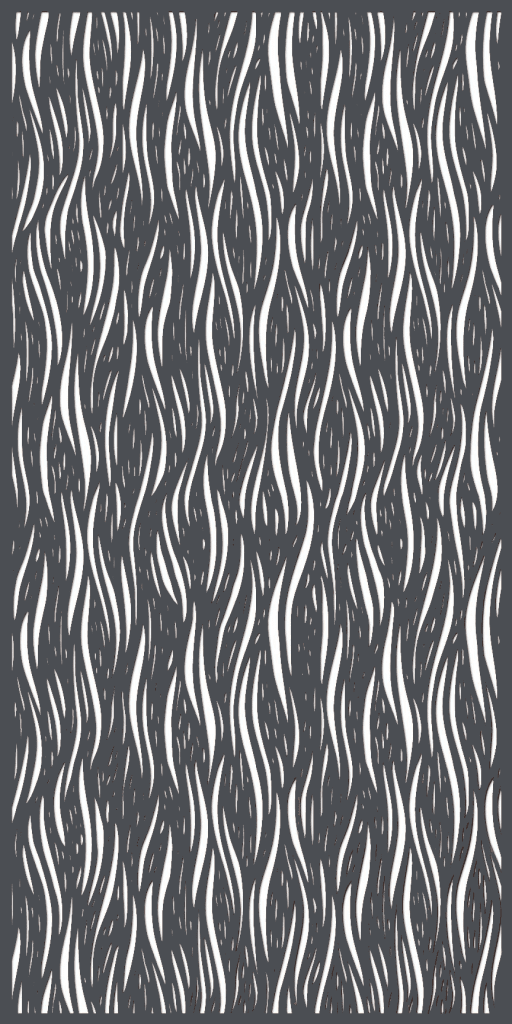

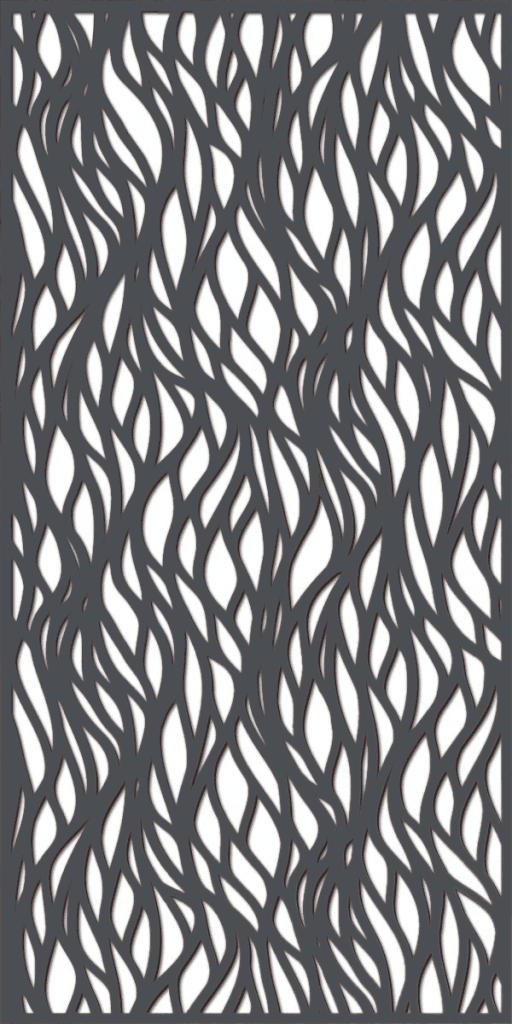

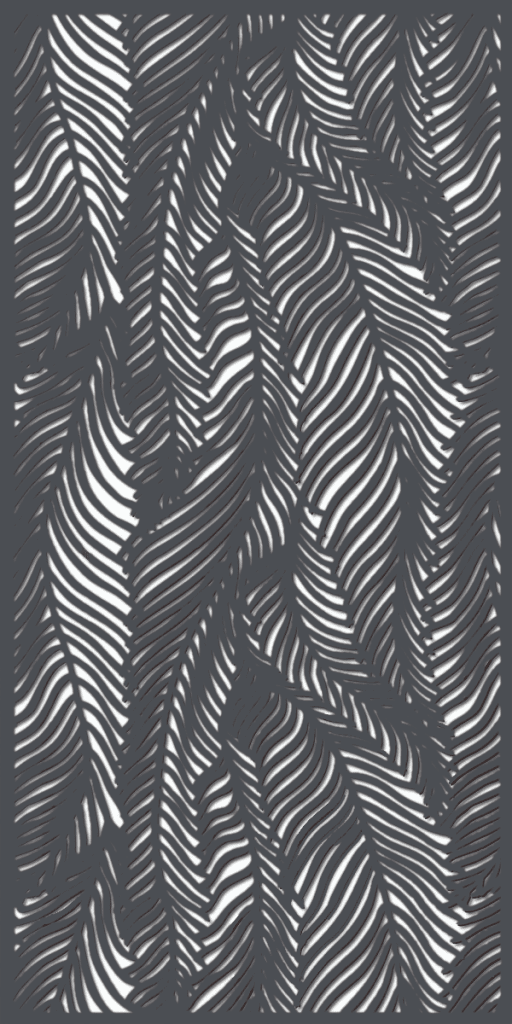

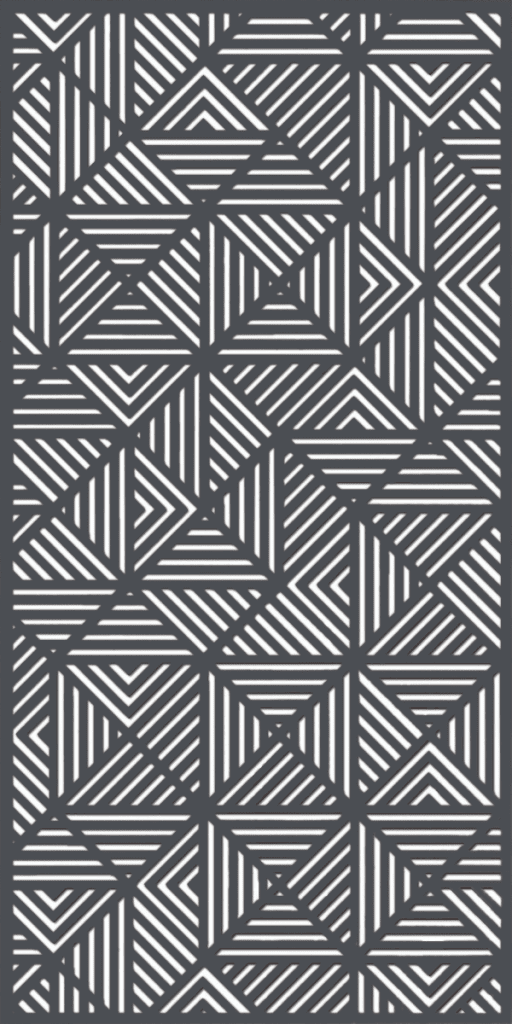

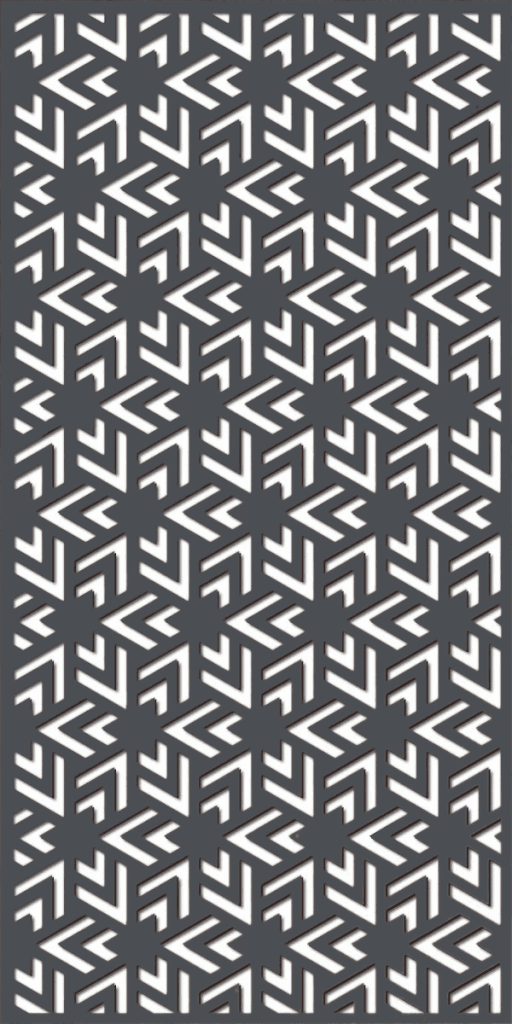

Pattern Sample: